posted

On Friday, April 25, 2025

in

Blog

Keeping your equipment clean bodes well for yourself and your visitors. It shows you care, take ownership for your property, and more than likely will be respectful of other’s property, too. So why not do what’s best for your welding table and/or ancillary equipment? UltraOx® them!

Why You Should UltraOx® Your Welding Table

Why You Should UltraOx® Your Welding Table

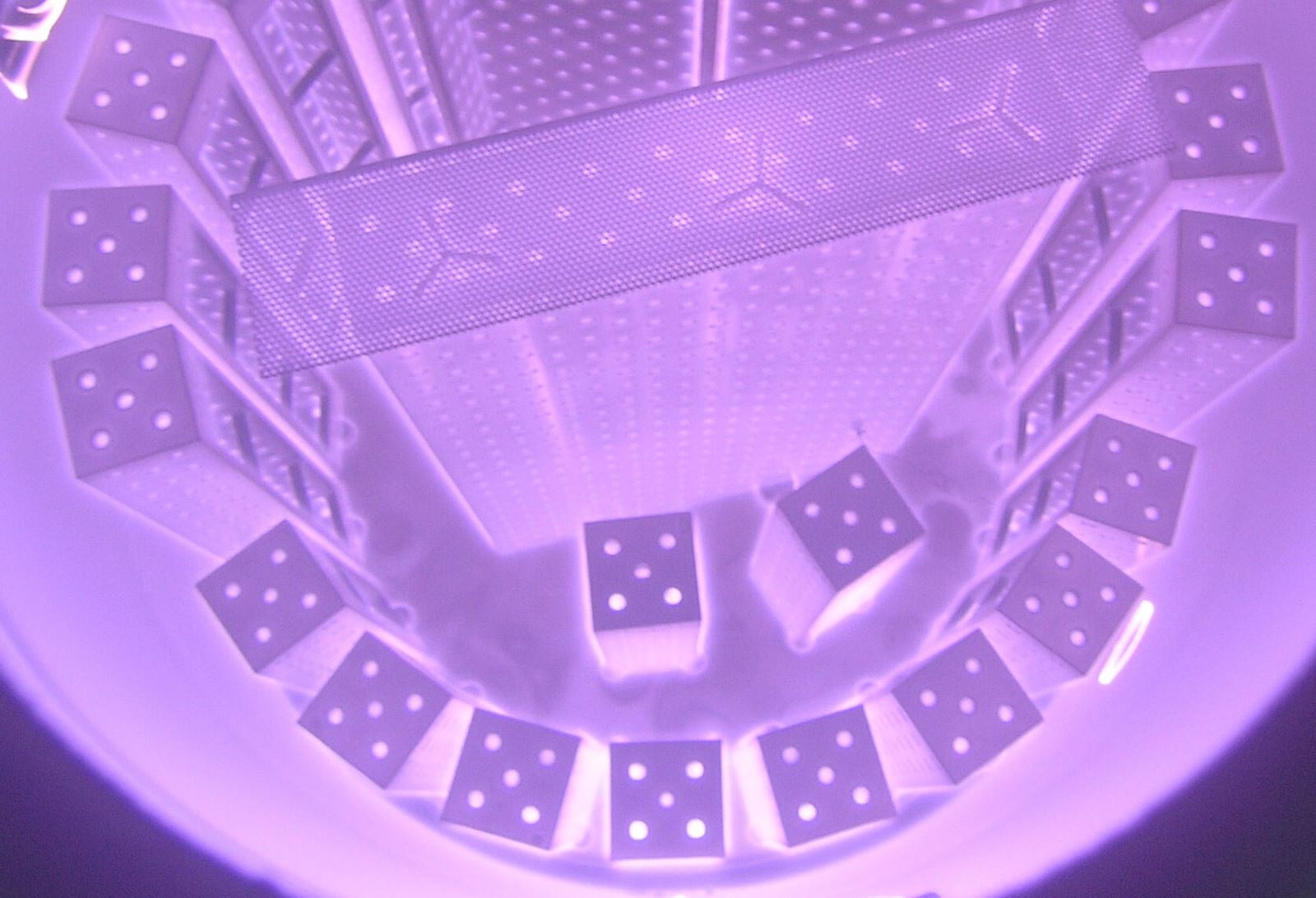

UltraOx® is Advanced Heat Treat’s (AHT) trademark process for ferritic nitrocarburization and oxidation treatments. Its three-layer surface protection enhances wear, toughness and corrosion resistance.

AHT has seen growth with its UltraOx® in welding applications. Many such customers looking to improve overall toughness, cosmetics, and clean-up of weld spatter have sought out its enhanced surface treatment. And now that tariffs are playing a significant role in overseas manufacturing, evaluating such processes as UltraOx® may be more fitting than ever.

Many welders complain of stiction of weld material to their table. While welding, excess matter will fly off the welder and onto the table, leaving little beads of welding matter. The welders will literally manually remove the matter by taking a tool steel scraper to the table and scraping the surface, adding non-value manpower, excess weld beads, and potentially damaging the table.

With UltraOx®, You'll See Benefits Such As:

- Weld spatter can be easily removed with simple swipe of the towel or glove

- Aesthetically appealing black finish

- Engineered three nitride layers to enhance wear resistance, lubricity and toughness

- Minimal to no movement on extremely large and/or long componentry

- Scratch resistance

- Corrosion resistance

- Extended life of the table

- Few size limitations - can accommodate tables/components of all sizes due to AHT's large equipment

- Various ferrous alloy materials could be used to manufacture table and maintain cost competitiveness

Take Care of Your Welding Tables with UltraOx® - available only at Advanced Heat Treat Corp.

Take Care of Your Welding Tables with UltraOx® - available only at Advanced Heat Treat Corp.

REQUEST AN ULTRAOX QUOTE TODAY

- ultraox®