posted

On Wednesday, August 19, 2020

in

Blog

The Challenge:

Large Part Size, Large Heat Treat Equipment Needed

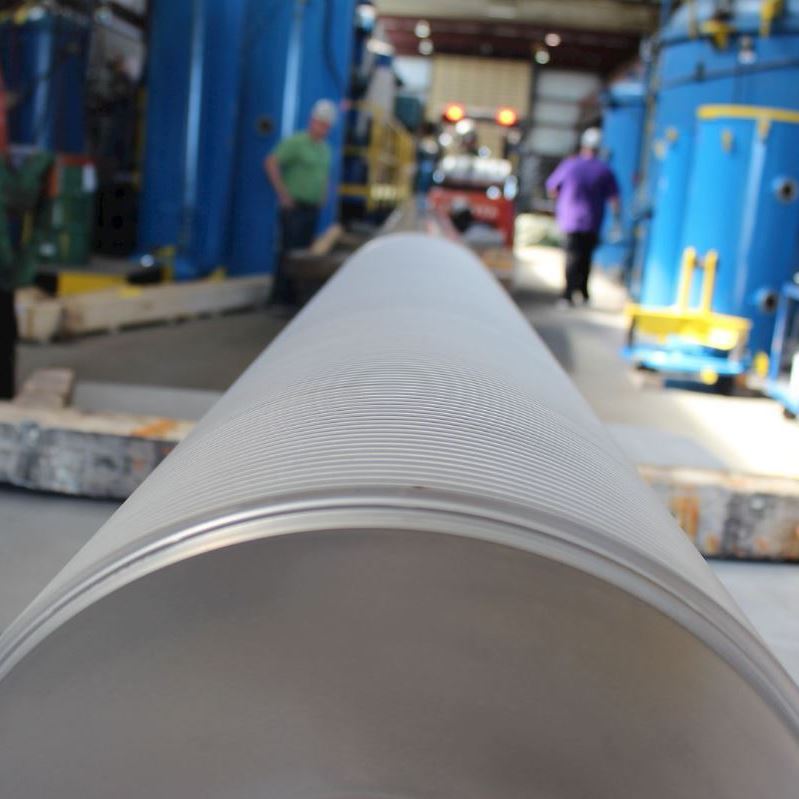

A large manufacturer to the US Military needed to heat treat a critical part to meet engineering print requirements. It was important that the part's dimensions not change as that would render it unusable for this particular application. Another challenge was that the part was very large in size.

The manufacturer needed a large nitriding vessel, the ability to load the part vertically, and a heat treater with the experience/expertise to nitride something of this magnitude.

The Solution:

AHT with Size Capabilities up to 360" in Length

The manufacturer decided to work with AHT on this project because of AHT's large size capabilities and vast nitriding experience. AHT has offered nitriding since 1981 and has over 50 nitriding vessels between its locations in Iowa, Michigan and Alabama, providing its customers with unparalleled knowledge and capacity. (RELATED: Click here to see nitriding size capabilities.)

AHT worked with the engineers, welcoming them onto the shop floor and meeting with involved parties such as quality, operations, metallurgy and more.

Customer Feedback

“The critical nature of the part and the recovery to keep the project on schedule was paramount. AHT was able to host our engineers during the process and the teamwork between our two companies made the outcome a success for our company and our customer. Thank you AHT!"

Do you have a component that requires a large nitriding vessel? Do you need a heat treater that will provide advice rather than just simply fulfill a PO? Get a hold of an AHT rep today.

REQUEST A QUOTE

- customer story

- defense

- nitriding