posted

On Wednesday, September 25, 2024

in

Blog

Q&As with Elliott

Prior to becoming our Michigan sales representative, you spent a year in AHT’s professional rotation employee program. Tell us about the program.

As part of this program, I rotated through Quality, Metallurgy, Sales, and Operations, spending 1-2 months in each department and eventually visiting all four AHT locations.

I learned about operational processes such as fixturing, masking, shipping, part loading, cleaning, etc.; gained hands-on experience cutting and analyzing samples with Metallurgy; and assisted the Quality Department with revising our Quality Manual and rewriting the Quality Policy. Toward the end of the rotational program, I joined Sales where I shadowed customer visits and learned about pricing and quoting. Sales is the department I remain in today, focusing on my territory (Michigan, Ohio and Indiana) and assisting our other Michigan customers, too.

This experience gave me a well-rounded understanding of our heat treat services, our customers' parts, and how our company operates.

What services are offered at Advanced Heat Treat Corp. in Monroe, Michigan?

Our main processes are ion / gas nitriding, UltraOx®, and stress relieve.

Our Michigan location has the unique capability to accommodate some extremely long parts. In fact, recently, we intentionally split the lid of a nitriding vessel in two, loaded the part down into the vessel with the bottom part of the lid already there, and then reassembled the lid with the part in the vessel. It was a tedious process, but our maintenance and production teams nailed it!

VIEW MICHIGAN AHT'S SERVICES

Tell us about some of the nitriding projects you’ve seen in Michigan.

One project I have been working on recently are a set of parts that are supposed to screw together. They are currently salt bath nitrided, but the residue from the salt bath left gunk in the threads and prevented them from being attached. This is not a problem with gas nitride, which is an atmosphere-based process.

Another project that I have been working on is a part that is machined, induction hardened, machined, and chrome plated. If large case depth is not critical (induction gets much deeper case than nitriding), switching to ion nitride is a great alternative. It allows the customer to send a finished part and the ability to still selective harden with mechanical masking. This saves on transportation costs and lead time for the customer.

When you’re not working, how do you like to spend your free time?

When you’re not working, how do you like to spend your free time?

In no particular order, I enjoy disc golf, board games, playing / watching sports and yard games, listening to podcasts, reading, and playing the drums (which I sadly don’t do much anymore).

Pictured: Elliott disc golfing at The Canyons at Dellwood Park in Illinois, the #17 course in the world.

What is one thing people may not know about Elliott Schmidt?

In the last few years, I have found that I enjoy reading poetry and short stories. I read the “poem of the day” on PoetryFoundation.org as often as I can.

What is one thing people may not know about AHT?

AHT started with ion nitriding back in 1981 (before it was popular). Ion nitriding is famous for the purple glow from the plasma being generated. That is why our company color is purple! 40+ years later, AHT purple is still easily recognizable and stands out from the rest of the heat treat industry.

In your opinion, what sets AHT apart from the competition?

The main thing that sets AHT apart is our technical expertise and customer communication.

The AHT team is dedicated to helping their customers find the right solution for their parts and we have many people capable of doing this. We have multiple metallurgists on staff and have dozens of years of experience across our plant managers, lab technicians, and sales team members. As someone who doesn’t have as much experience yet, I am lucky to be surrounded by a team that is always willing and able to help, and I am learning more from them every day.

What advice or tip would you give our customers?

When it comes to a heat treat quote request, the more information you provide, the faster we can provide you with a quote. There are certain things that we have to know in order to quote/process parts, and having those provided up front means we don’t have to ask for them!

Some important information to include when you request a quote:

- Material (and its core hardness / previous processing temperature)

- Some form of part identification (Part #, description)

- Heat treat process

- Heat treat requirements (like case depth, surface hardness, etc.)

- Heat treat specifications

- If masking is required

REQUEST A HEAT TREAT QUOTE NOW

In your new position, you’ve been traveling more often and meeting customers. How has this benefited your learning and/or the customer service you provide?

One of my favorite TV shows growing up was called “How It’s Made”. I have always enjoyed learning how things are created / manufactured. Touring customer facilities has been a great learning experience in my new role. I can better understand the scope of what customers do, what their needs are, and how AHT can best help them.

Now, a series of quick random questions:

- Your Educational Background: Bachelor of Science in Chemistry, Minor in Physics

- Favorite Book(s): The Giver (Lois Lowry), Gods and Generals (Jeff Shaara), Red Rising (Pierce Brown)

- First Job: Soccer Referee, part-time on AHT Shop floor

- Favorite Food: Italian, Bread

- Favorite Snack: Cheez-Its

- Least Favorite Food: Seafood

- Favorite Vacation: Wherever family is

- Favorite Board Game: Root

- Most Interesting Historical Period: Civil War

- Favorite Sport: To play: Soccer, Disc Golf. To watch: Formula 1

- Favorite Team: Detroit Lions

- Coolest Place You’ve Been: National Air and Space Museum, Gettysburg, and Breckenridge, CO

- Favorite Animal: Snow Leopard

- Role Model or Person You Admire: My dad

- Bucket List Experience: Disc golf in the Nordic countries, particularly Finland; Museum of the Bible

Have A Question for Elliott Schmidt? Contact him at 319-232-5221 or Via Our Website.

FILL OUT CONTACT FORM & GET A RESPONSE WITHIN ONE BUSINESS DAY

Bonus Question:

One of AHT’s core values is PASSION. Tell us about some of your passions, aside from heat treatment.

One of my biggest passions is learning. I love to collect facts and information, and you never know what topic will catch my interest on a given day. But once my brain is curious about something, I have to keep learning more (current interest - disc golf). Alongside that, I enjoy sharing that knowledge with others. There’s no real fun in learning cool things if you can’t share it with someone else. In the past, I have had a few teaching / coaching related opportunities, and those have always been a blast.

One of my biggest passions is learning. I love to collect facts and information, and you never know what topic will catch my interest on a given day. But once my brain is curious about something, I have to keep learning more (current interest - disc golf). Alongside that, I enjoy sharing that knowledge with others. There’s no real fun in learning cool things if you can’t share it with someone else. In the past, I have had a few teaching / coaching related opportunities, and those have always been a blast.

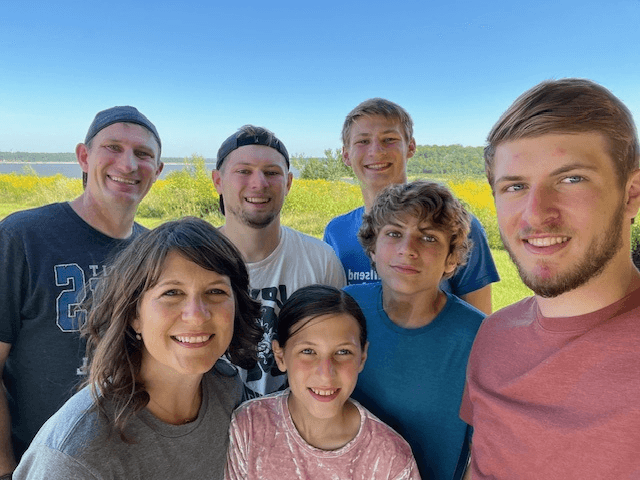

I am also passionate about family (pictured). My favorite way to spend time is doing things together with my siblings, cousins, grandparents, etc. Whether it’s an activity like pickleball, playing card games, or just sitting together eating food and watching sports, there is always a lot of joy and laughter. I am fortunate to work at a place where this passion is shared and a part of the culture.

- meet monroe

- meet the team